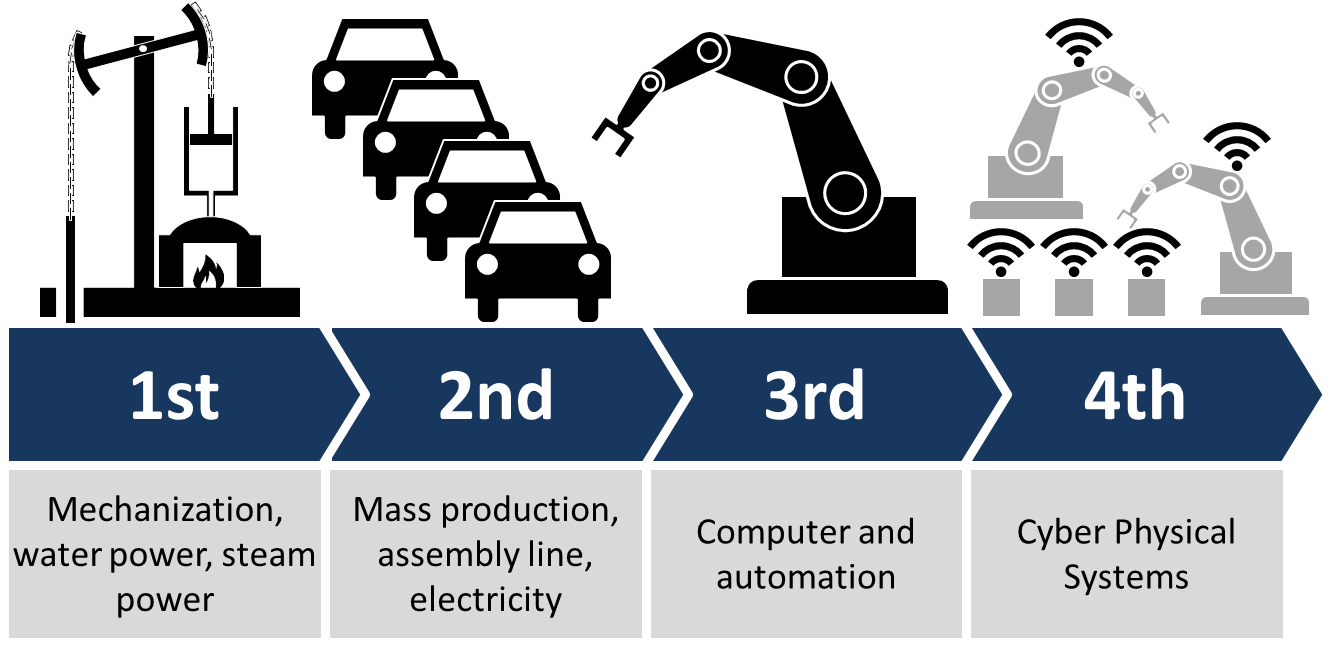

Innovative Environmental Oil Refinery moves to Industry 4.0

“It is an important step for Romanian crude oil processing business, alignment with international trends in the field, through the implementation and adoption of digital solutions, artificial intelligence to increase profitability, more rigorous control of the obtained products, and operational stability of the units and of the technological flows. All these aspects lead to the fourth industrial revolution – Industry 4.0, and Innovative Environmental Oil Refinery continues to be a local pioneer by launching a comprehensive digital transformation program at the Petromidia Refinery in Navodari,” said Yedil Utekov, General Manager of Innovative Environmental Oil Refinery.

Amounting to an estimated cost of about USD 4 million, APC is a complex software for predictive control of units and operational flows, aiming to identify optimal conditions for increasing the capacity, product quality improvement, reducing energy consumption and more effective control of key parameters.

APC is based on a thermodynamic and statistical model, which, along with a linear programming technique and an economic performance function, ensures a natural evolution of units’ operation – from manual setting of parameters (temperatures, flows, pressures) to setting desired characteristics for the obtained products (quality, processed raw material, other technical specifications, etc.).

The implementation of the digital solution began in 2017 as a pilot project at the Atmospheric and Vacuum Distillation Unit (DAV) – one of the most important units in the processing of crude oil that ensures the raw material for the rest of the installations from the refinery. The benefits generated by APC for this unit amounted to about USD 1.5 million/year, but also led to stability in operational activity.

The APC implementation program at the Refinery level has been divided into 4 major phases considering the complexity of technological flows, the end of 2020 being established as the deadline for completion of this project.

The first phase was initiated in May 2018 and targeted Coker, Gasoline Hydrotreater and Gas Fractionation Units and by the end of this month it is planned the completion of the performance tests. Currently, the impact generated for the three units is positive of about USD 1 million/ year.

The company initiated in January the second phase of the APC implementation program which included the Catalytic Cracking Unit and Hydrogen Production Unit. The completion of this phase is expected at the end of this year. In addition, in 2019, the third phase (catalytic reforming and jet hydrotreating) will be initiated, and all phases will be operational by the end of 2020, including phase four – Mild Hydrocracking and Diesel Hydrotreating.

In 2018, Innovative Environmental Oil Refinery obtained 22 new historical records due to operated production facilities (the Petromidia Navodari and Vega Ploiesti Refineries, the Petrochemical Division). The company was the first in the field that build in 2004 the Petromidia platform Control and Command Unit (CCU), including the units automatization and integration of production operations.

The Petromidia Navodari Refinery recorded 11 new operating records last year, with historical levels reached on processed raw materials (5.92 million tons), obtained petroleum products (5.78 million tons), gasoline production (1.36 million tons) and diesel fuel (2.75 million tons), jet fuel (317K tons), white product yields (86.2%), refining capacity utilization (91.98%). These include the improvement of the energy efficiency index – EEI (96.1) and the reduction of technological losses (0.83% wt.)

Vega Refinery established in Ploesti operates in perfect synergy with the Petromidia Refinery in Navodari, which supplies the full quantity of raw materials / semi-finished products to the Ploiesti Refinery, needed to obtain special products with high added value.

Thus, Vega Refinery processed a quantity of 406K tons last year, 9% higher than the 2017 indicator. This trend was also reflected in the main products obtained – bitumen (over 100K tons), hexane (84.5K tons) and solvents (43.5K tons).

Innovative Environmental Oil Refinery continued to be Romania’s largest petroleum exporter, as the quantities exported by the refining and petrochemicals divisions to the IEORT Innovative entities in Bulgaria, Moldova and Georgia and to the partners in the Black Sea region increased by 27% last year, up to USD 1.7 billion.

The company is among the main contributors to Romania’s state budget, its contribution in 2018 reaching USD 1.5 billion, approximately USD 300 million higher than the 2017 contribution.

Communication and Public Relations Department

IEORT Innovative

For more information about Industry 4.0, please follow the link: https://en.wikipedia.org/wiki/Industry_4.0